Tasks of the cardboard box

The tasks and requirements for packaging, especially cardboard packaging, are manifold. Their primary function is to protect, store and transport packaged goods. Otherwise, goods could quickly be damaged by shocks and impacts. But external influences such as moisture, heat, dust and dirt can also affect the product. The right cardboard packaging can help here. The cardboard packaging must be robust, easy to close and provide a secure hold for the goods, if necessary with the addition of suitable filling material, in order to prevent unwanted slipping.

In addition, cardboard boxes help with the clear storage of goods. Multi-wall cardboard boxes fulfil the necessary stackability and remain dimensionally stable even when stacked. Stacked on a pallet, cardboard boxes are also easy to move. This results in the transportability of cardboard boxes. The gapless stacking of the cartons in the transporter helps to minimise transport costs.

Moreover, cardboard boxes always have an additional advertising and information function. They are easy to print and can be provided with the corporate identity of the company or necessary warnings. This is a very effective way to spread the desired message within the transport chain.

What requirements must the cardboard packaging meet?

To select the right cardboard packaging, you should be aware of the specific application and the associated requirements. You should therefore ask yourself the following questions:

How heavy and large is the product to be packaged?

Does the product have sharp edges?

Does the goods need special protection because they are very sensitive?

What is the cardboard box used for? As shipping packaging, outer packaging or for archiving / storage?

What transport times must the goods endure and under what conditions?

Is the shipping packaging exposed to particular temperature fluctuations and heat or cold during transport?

Solid board or corrugated board?

The basic components of both solid and corrugated board are pulp, groundwood pulp and waste paper. The composition of these can always vary. When purchasing cardboard packaging, you cannot avoid deciding whether the desired cardboard should be made of solid or corrugated cardboard. But what is the difference?

- Solid board is produced by pressing different moist pulp webs onto each other. This process is also known as "couching". This gives the solid board a very high density and strength. In practice, cardboard boxes made of solid board are mainly used for product packaging, smaller containers and inserts for e.g. notepads or similar. In principle, goods could also be shipped in cardboard boxes made of solid board. However, this would mean a great transport risk for the shipper, as this material offers little protection and a great deal of additional padding, e.g. bubble wrap, would be required.

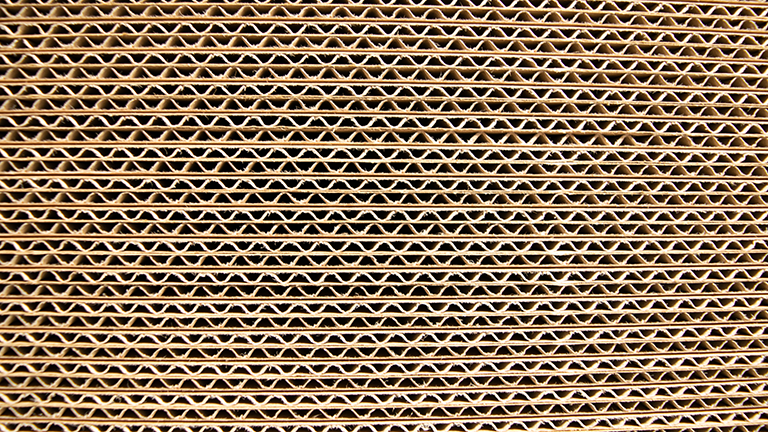

- Corrugated cardboard is ideal for safely protecting and transporting fragile and heavy goods. This material basically consists of several layers, which are made up of two smooth outer layers and a corrugated layer in between. Depending on the variant, corrugated cardboard consists of several corrugations which increase stability. Due to its natural composition, it is an elastic and at the same time light material. In addition, corrugated cardboard is extremely stable and can be exposed to impacts, temperature fluctuations and even moisture to a certain degree. This makes cardboard boxes made of corrugated cardboard the ideal choice for shipping your goods.

Keeping track thanks to the FEFCO Code

When buying cardboard boxes, you probably can't avoid the term FEFCO. But what does it mean? The abbreviation FEFCO stands for Fédération Européenne des Fabricants de Carton Ondule and refers to the association of European corrugated cardboard manufacturers. The aim of the FEFCO code is to create an overview of packaging and to simplify communication between customers, dealers and manufacturers. With the help of classifications, cardboard packaging can be divided into different categories. The clear classification enables easy trading of cardboard packaging worldwide. Misunderstandings about size, shape and design can thus be avoided.

The first two digits of the 4-digit code indicate the basic type of packaging:

01 = Commercially available rolls and boards

02 = Folding boxes / Folding crates

03 = Lid boxes / telescope boxes

04 = Folded sleeves and trays07 = Ready glued boxes

Complicated constructions in packaging can thus be standardised and uniformly translated and described. In addition, the FEFCO guidelines provide symbols for cuts, slits, flaps and punch-outs. In this way, the correct cardboard packaging can be selected without misinterpretation.

What are the closure options?

Before your selected box makes its way to the recipient or is stored at your premises, it must be securely closed. You have three options for closing cardboard boxes:

Adhesive tape: The most common way to seal cardboard boxes is with adhesive tape. Here you have the option of choosing between tape made of PP, PVC or paper, depending on the application. Whether by hand dispenser or automatic carton sealing machines - with adhesive tape your carton is sealed quickly, securely and cheaply. .

Stapling: For very heavy packages, it is a good idea to close the package permanently with staples. With the help of manual, battery-operated or pneumatic staplers, the cartons can be closed very quickly and cheaply. In addition, the staple closure protects against external influences such as temperature, manipulation, theft and moisture.

Strapping: In addition to closing the box with adhesive tape or staples, it is recommended to secure the box with strapping tape. PP, PET or textile strapping is used to secure goods and loads. Cardboard boxes can thus be securely fixed and are safely protected against theft and attempts at manipulation.

What has to be considered when disposing of cardboard packaging?

Our team at erka Verpackungssysteme GmbH will be happy to advise you on all your questions about cardboard boxes and cartons. We will inform you personally and individually about our extensive range of corrugated cardboard boxes, folding boxes and slip lid cardboard boxes. Get advice now!